How to Choose a Bandsaw Blade

Many buyers are victims of manipulations by much-hyped product adverts. Such may not guarantee high-quality. So, how will we distinguish wheat from tares? The first thing is to subject your product to different variables.

If the bandsaw has a correct blade, it will make cuts with precision. The big issue here is to locate a suitable blade. Several choices exist to meet your preferences. This guide will uncover some of the items you must exhaust before deciding to get your ideal blade.

If the bandsaw has a correct blade, it will make cuts with precision. The big issue here is to locate a suitable blade. Several choices exist to meet your preferences. This guide will uncover some of the items you must exhaust before deciding to get your ideal blade.

If the bandsaw has a correct blade, it will make cuts with precision. The big issue here is to locate a suitable blade. Several choices exist to meet your preferences. This guide will uncover some of the items you must exhaust before deciding to get your ideal blade.

If the bandsaw has a correct blade, it will make cuts with precision. The big issue here is to locate a suitable blade. Several choices exist to meet your preferences. This guide will uncover some of the items you must exhaust before deciding to get your ideal blade.

Bandsaw Blade Width

One needs to know the width of the blade. We recommend that you select the widest blade possible based on the kind of cuts you make. For example, when you cut curves, the blade’s width determines the radius size for cutting. You can opt for smaller blades when dealing with smaller radius cuts. We reserve larger radius widths for re-sawing straight line cuts. The best practice is to consult the device’s manual to know the minimum and maximum width it tolerates. The right blade width for your tasks prevents breakage while achieving decent cuts. For example, you require the narrow blade width to cut the correct radius.Number of Teeth

Here, you need to strike a balance between the feed rate and finishing. If the blade has fewer teeth, it cuts faster, featuring a rougher finish. In the same vein, the one with more teeth cuts slower with a smoother finish. If you desire to maintain cutting precision, then keep at least three teeth. Such a design enhances stability and accuracy. The cool thing is such a strategy is applicable for both metal and wood materials.Teeth per Inch

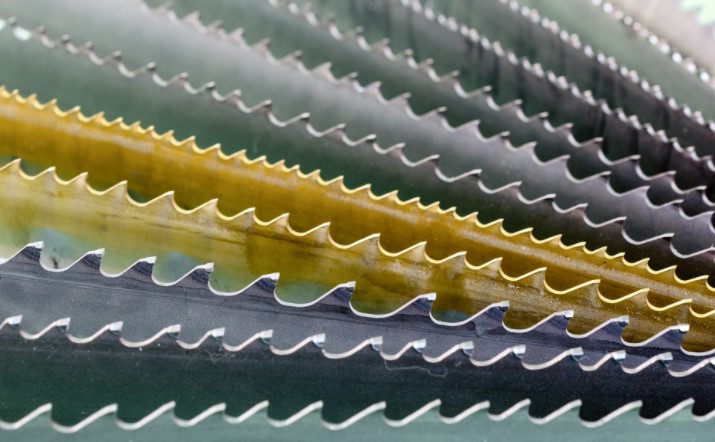

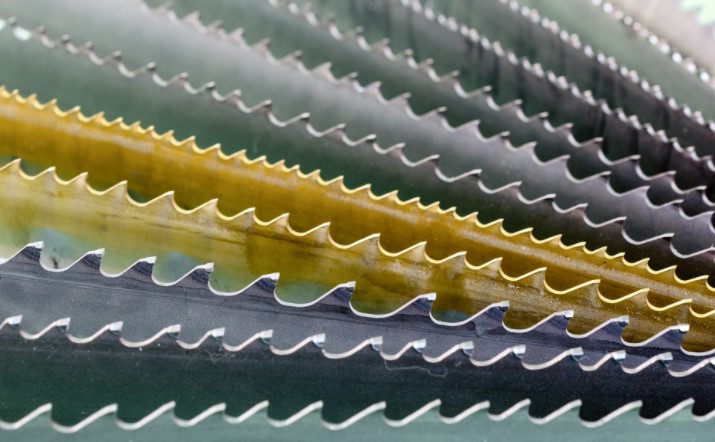

The carpenter can achieve smooth, more refined, and smooth cuts by using more TPI. It is advisable to use higher TPI configurations on thinner materials. For thicker materials, you can use a low TPI blade with a higher feed rate. One can use coarse tooth blades featuring 2 to 3 teeth per inch (TPI). Again, you can use a 4 TPI blade for coarse and fast ¾ inch materials. For slower and smooth cutting, you can involve a 14 TPI tooth blade. However, you can use a blade that ranges between 6 to 8TPI for general-purpose performance. That applies to both wood and metal materials. You need a finer blade that ranges between 18 and 32 TPI for plastic and thinner metals under ¼ inch.Tooth Type

There are different types of blade teeth to suit specific tasks. These are as indicated in the below segment.- Regular Teeth: it is suitable for higher TPI blades. The great advantage of such teeth is that they provide smoother cuts in the woods. You can apply it around the curved of your workpiece. They are available in most regular settings.

- Hook Teeth: this option has wider spaced teeth and features a 10-degree rake angle. They take the shape of a fishing hook. Such enhances aggressive cuts in hard-to-cut woods. The purpose of that teeth angle is for faster material cuts into the thicker medium.

- Skip Teeth: it has wider spaced teeth necessary for less aggressive and smooth cuts in wood. Since it has zero degrees rake angle, it is ideal for re-sawing. The design-assist in preventing being stuck when cutting softer wood.

- Raker Teeth: it is an arrangement whereby it has one tooth that points one way during the next opponent. They are all on a straight blade.

- Alternate Teeth: It has a similar style to a raker type, although this style lacks a straight blade.

- Wavy Teeth: Such are groups of blades that point in opposite directions from one another. We apply them for thin and small projects.

- Variable Pitch Teeth: It consists of alternating sets of various-sized teeth. Such provide a fast cut and a smooth finish. You can apply it for cutting curves and joinery.

Blade Set

One should select an appropriate setting to get a balance between the air and the work piece. A suitable size should be in the 80/20 proportion. Such means that there is 80% sawdust and 20% takes the place of air under ejection. Let the sawdust be warm to the touch and not too cold or hot. You can prevent tooth marks by avoiding too many sets. Also, too little set can restrict airflow. As such it limits the blade performance of pulling the sawdust from the cut. Such could lead to premature blade breakage when it meets hot packed sawdust.Bandsaw Blade Materials

Different manufactures use various materials to construct bandsaw blades. For example, carbon Bandsaw blades feature aluminum, carbon, and mild steel. Others come from metal alloys such as carbon steels or stainless steel. The following are properties of the suitable material for blade construction.- a) Toughness: It is a suitable property for preventing fracturing or chipping in blades.

- b) Hardness: It keeps the blades safe when subjected to high heat levels.

- c) Wear Resistance: It should serve one for the right period before thinking of a replacement.

Bandsaw Types

You will encounter different types of bandsaw for your selection in the market. Such include:-

Floor Saw

-

Hand-Held Saw

-

Meat Band Saw